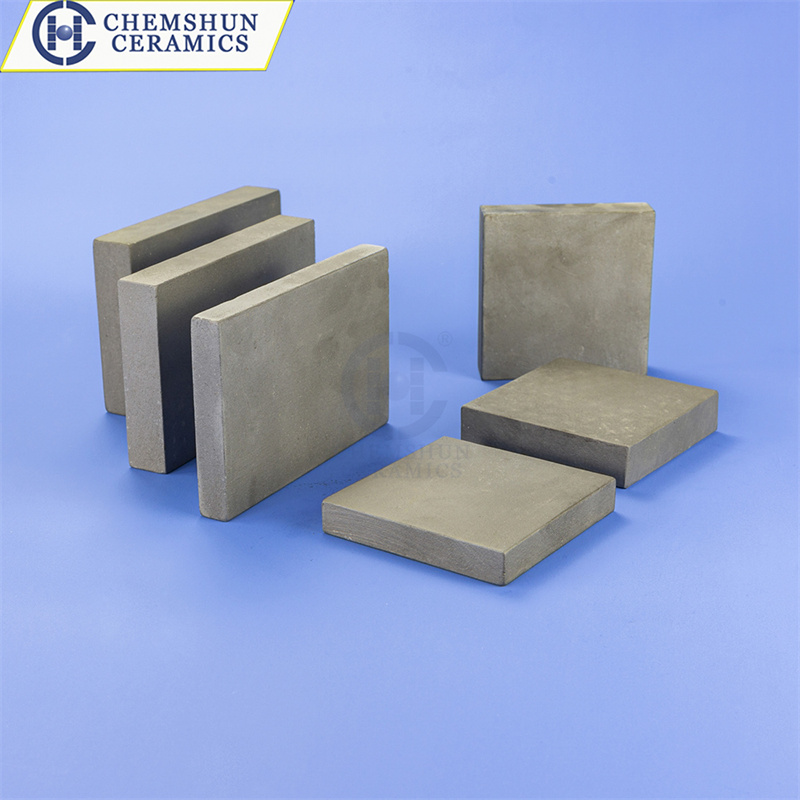

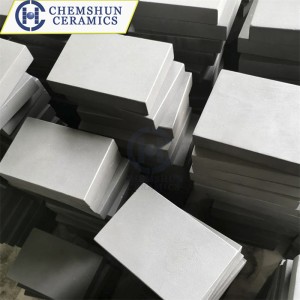

I-Rection Bonded Silicon Carbide Tile

Izinto eziluncedo kwiReaction Bonded Silicon Carbide

1) Ubuninzi obuphantsi.

2) Ukumelana nokubola.

3) Ukugqoka ukuxhathisa.

4) Ukumelana ne-oxidation.

5) Ukuxhatshazwa kwe-abrasion.

I-6) Ukuchasana kakuhle kwe-thermal shock (ngenxa ye-coefficient yokwandisa i-thermal ephantsi kunye ne-conductivity ephezulu ye-thermal).

7) Amandla agqwesileyo kwiqondo lokushisa eliphezulu.

I-8) Ulawulo olufanelekileyo lwe-dimensional yeemilo ezinzima.

Nxiba iimveliso ezixhathisayo: ipleyiti ye-silicon ye-carbide, isitena se-Silicon carbide, i-Pipe lining, i-Pipe Cone, i-cyclone, njl.

Ifenitshala yeKiln: Ipleyiti, iBeam, Roller, Burner Nozzle, umqadi ojikelezayo, umqadi osisikwere, umngxunya womngxunya.

Abanye: Imilomo ye-Desulfurization

Ukusetyenziswa kweReaction Bonded Silicon Carbide:

I-Reaction bounded silicon carbide ibonakalise ukuba lolona khetho lubalaseleyo lwemathiriyeli kwizicelo zokunxiba ezinje ngeelayini zemibhobho, iiNozzles, imibhobho yokulawula ukuqukuqela kunye nezinto ezinkulu zokunxiba emigodini kunye namanye amashishini.

Eyona Parameter

| Iipropati | Iiyunithi | SiSiC/RBSIC |

| Ubuninzi bobuninzi (SiC) | V01% | ≥85 |

| Unizi lolwapho kuyiwa khona | g/cm3 | 3.01 |

| I-porosity ebonakalayo | % | <0.1 |

| Imodyuli yokugqabhuka kwi-20℃ | Mpa | 250 |

| Imodyuli yokugqabhuka kwi-1200℃ | Mpa | 280 |

| Imodyuli ye-elasticity kwi-20℃ | Gpa | 330 |

| Ukuqina kokwaphuka | Mpa*m1/2 | 3.3 |

| I-Thermal Conductivity kwi-1200℃ | wm-1.k-1 | 45 |

| Ukwandiswa kweThermal kwi-1200 ℃ | ii×10-6/℃ | 4.5 |

| Ukumelana nokothuka kwe-Thermal kwi-1200 ℃ | Kakuhle kakhulu | |

| I-Coefficient yokushisa ukushisa | <0.9 | |

| Ubushushu bokusebenza obuphezulu | ℃ | 1350 |

Ubungakanani

inokwenziwa ngokweemfuno zabathengi.

Inkonzo

Samkela iiodolo zesiko.

Ukuba ufuna ukwazi ulwazi oluninzi ngemveliso, wamkelekile ukuba uqhagamshelane nathi kwaye siya kukunika eyona mveliso ifanelekileyo kunye nenkonzo ilungileyo!