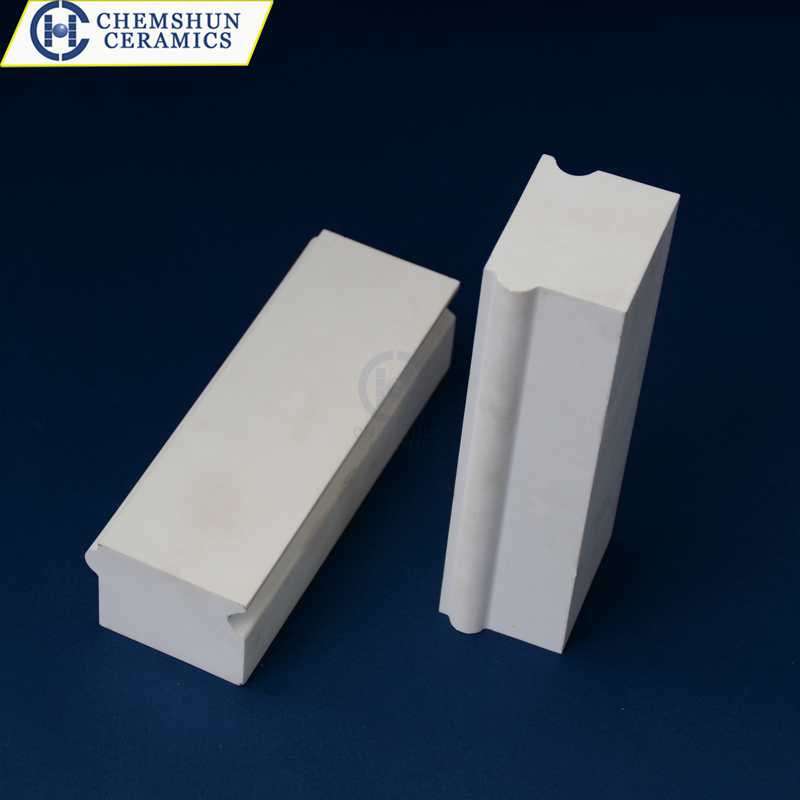

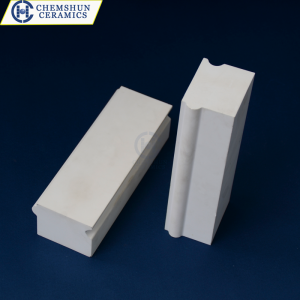

Ball Mill Alumina Lining Brick

Iinzuzo zeMveliso

I-1) Umxholo oyintloko kukucoceka okuphezulu kwe-Al203 powder.

2) Ipropathi egqwesileyo yokunxiba.

3) Ubuninzi obuphezulu kunye nobunzima.

4) Gqibezela ubungakanani bemigca yezitena ukuze kube lula ukufakwa.

Isicelo

1) ibhola lokusila, umatshini wokusila ibhola, imbiza yokusila, ilitye lokusila, ilitye lokusila, iAtrition Mill, ilitye lokusila, umatshini wokusila, ibhola lokusila.

2) ukuqhekeza izityalo, i-ceramisc, i-metallurgy, iglasi, i-porcelain enamel, i-pigment, iikhemikhali, iMigodi, iSamente, amashishini okuvelisa amandla.

Ukuhlelwa okuphambili

I-Alumina yokuSila iMedia, i-Alumina Lining Brick, i-ZrO2 yokuSila iMedia

| Into | Igama | Ubude (mm) | Ubude (Ukutyeba) (mm) | Ububanzi-1 (mm) | Ububanzi (mm) |

| 1 | Isitena esixande | 150 | 40~77 | 50 | 50 |

| 2 | Isiqingatha sesitena seRectangular | 75 | 40~77 | 50 | 50 |

| 3 | Isitena seleli | 150 | 40~77 | 50 | 45 |

| 4 | Isitena esibhityileyo | 150 | 40~77 | 25 | 22.5 |

| 5 | Isiqingatha sesitena seleli | 75 | 40~77 | 50 | 45 |

Iphepha leDatha lobuGcisa

| Umxhuzulane okhethekileyo (g/cc) | >3.60 |

| I-porosity ebonakalayo (%) | 0 |

| Amandla eFlexural (20ºC, Mpa) | 270 |

| Amandla acinezelayo (20ºC, Mpa) | 850 |

| Ukuqina kwe-Rockwell (HRA) | 80 |

| Vickers ubunzima (hv) | 1000 |

| Ubunzima bukaMoh (isikali) | ≥9 |

| Ukwandiswa kweThermal (20-800ºC, x10-6/ºC) | 8 |

| Ubungakanani beCrystal (μm) | 1.3~3.0 |

| Ukuqina Kokwaphuka (Mpa.M1/2) | 3-4 |

| Elona qondo lobushushu bokusebenza(ºC) | 1450 |

Inkonzo

Siyazamkela ii-odolo zesiko, sinokuyila izitena zokusila ngokuthe ngqo ngokwesayizi yebhola yomthengi kunye nobungakanani bomngxuma.

Ukuba ufuna i-design ball mill okanye ufuna ukwazi ulwazi oluninzi ngemveliso, wamkelekile ukuba uqhagamshelane nathi kwaye siya kukunika eyona mveliso ifanelekileyo kunye nenkonzo ebalaseleyo!