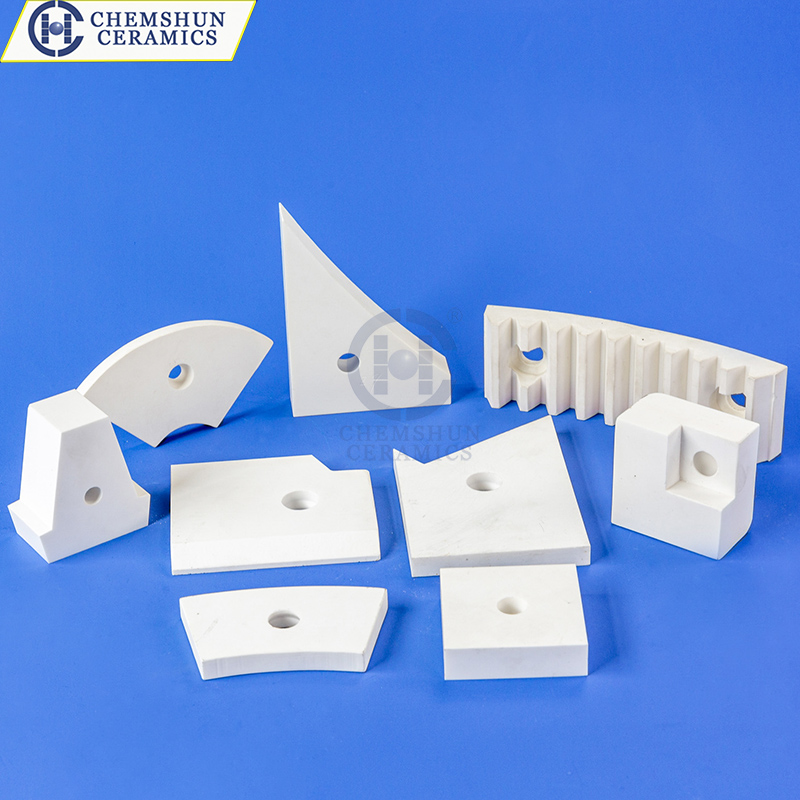

Iiseramics ze-alumina luhlobo lweeseramics zobunjineli, kwaye ukusetyenziswa okuqhelekileyo kwemihla ngemihla kweemveliso ze-ceramic kwahluke kakhulu.I-alumina ceramics zikwabizwa ngokuba yi-ceramics ekwazi ukumelana nokunxiba, kuba inokumelana nokunxiba okugqwesileyo, ukumelana nomhlwa, ukumelana nobushushu obuphezulu, ngoko ke isetyenziswa kakhulu kwintsimbi, amalahle, imigodi, isamente, iikhemikhali kunye namanye amashishini, lukhetho olulungileyo kumashishini. nxiba ukumelana.

Inkqubo yokwenza i-alumina ceramics ihlukaniswe ngokubanzi ngamanyathelo amaninzi: ukulungiswa komgubo, ukucofa, ukutshisa.

Ukwenza i-ceramics enganyangekiyo ngokusebenza kakuhle, kuyimfuneko ukukhetha umgubo we-alumina olungileyo, ubukhulu bayo buhlala bu-1μm okanye ngaphantsi.Kwinkqubo yokulungiselela umgubo, izongezo ezahlukeneyo kufuneka zongezwe ukulungiselela ipowder eneempawu ezahlukeneyo.

Iiseramikhi ze-alumina zinokuqulunqwa ngeendlela ezahlukeneyo.Iindlela ezisetyenziswa ngokuqhelekileyo kubumba ukucofa okomileyo, ukubumba i-grouting, i-extrusion, i-isostatic pressing molding, i-injection ye-injection, indlela yokugoqa, indlela yokucofa okutshisayo, indlela ye-gel, njl.Ngokubanzi, iiseramikhi ze-alumina ezenziwe ngokucinezela okomileyo kunye nenkqubo yokucinezela isostatic inobunzima obuphezulu kunye nokumelana nokunxiba.

I-Sintering alumina ceramics kwakhona linyathelo elibaluleke kakhulu.Phakathi kwabo, ukulawulwa kokushisa kwe-sintering yeyona nto ibalulekileyo, inquma ukuxinana, isakhiwo kunye nobomi benkonzo ye-ceramic.

Inyathelo ngalinye lemveliso yeiiseramikhi zealuminaifuna ulawulo lobuchwephesha kunye nobhaqo, ukuze kufumaneke iiseramikhi ezigqwesileyo ezinganxibiyo.

Ixesha lokuposa: Apr-17-2023