I-99.7% ye-Alumina Ceramic Baseboard

Isicelo

NjengeAlumina Substrate yepaneli yeLCD (PFD,PDF,TFT…) izixhobo zokuvelisa.

Kwishishini elikhulu le-LCD yeglasi yokuhambisa i-manipulator.

Kwizixhobo ze-lithography.

Uphawu

Ukucoceka okuphezulu kunye nokuqina kweekhemikhali

Amandla oMechanical aphezulu kunye nobunzima

Ukuxhathisa okuPhezulu kokuMnyama

Ukumelana nombane oPhezulu

Ubushushu obuphezulu Ukuya kuthi ga kwi-1700ºC

Ukusebenza ngokugqithisileyo kwe-Abrasion Resistance

Ukusebenza kakuhle kweInsulation

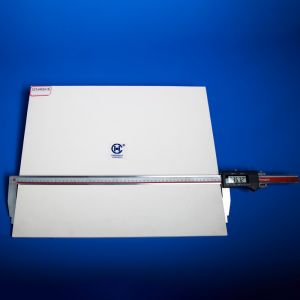

Ubungakanani obukhulu

Ubungakanani obukhulu

| Igama lemveliso | Chemshun ubukhulu obukhulu obuphezulu ubunyulu I-Alumina ceramic substrate ipaneli yeceramic |

| Izinto eziphathekayo | 99.7% ialumina |

| Ubungakanani obuqhelekileyo | 1200x500x20, 1400x900x30, ubungakanani obulungiselelweyo bamkelwe. |

| Umbala | Uphondo lwendlovu |

| Isicelo | Iphaneli yeLCD (PFD,PDF,TFT…) izixhobo zokuvelisa. |

| Min.Umyalelo | 1Pic |

Ulwazi lweMichiza / lomzimba

| Iyunithi | 99.7 iiCeramics zeAlumina | ||

| Iipropati ngokuBanzi | Umxholo we-Al2O3 | wt% | 99.7-99.9 |

| Ukuxinana | gm/cc | 3.94-3.97 | |

| Umbala | - | Uphondo lwendlovu | |

| Ukufunxwa kwamanzi | % | 0 | |

| Iipropati zoomatshini | Amandla e-Flexural(MOR) 20 ºC | Mpa(psix10^3) | 440-550 |

| IModyuli yeElastic 20ºC | I-GPa (psix10^6) | 375 | |

| Vickers Ukuqina | I-Gpa(kg/mm2) R45N | >=17 | |

| Ukugoba Amandla | Gpa | 390 | |

| Amandla okuqina kwama-25ºC | MPa(psix10^3) | 248 | |

| Ukuqina Kokwaphuka (KI c) | Mpa* m^1/2 | 4-5 | |

| Iimpawu zeThermal | I-Thermal conductivity (20ºC) | W/mk | 30 |

| I-Coefficient yokwandiswa kweThermal(25-1000ºC) | 1x 10^-6/ºC | 7.6 | |

| Ukunyangwa kweThermal Shock | ºC | 200 | |

| Ubushushu bokusetyenziswa okuphezulu | ºC | 1700 | |

| Iimpawu zoMbane | Amandla eDielectric (1MHz) | ac-kv/mm(ac v/mil) | 8.7 |

| IDielectric Constant(1 MHz) | 25ºC | 9.7 | |

| Ukuxhathisa uMqulu | ohm-cm (25ºC) | >10^14 | |

| ohm-cm (500ºC) | 2×10^12 | ||

| ohm-cm (1000ºC) | 2×10^7 |

Inkonzo

Samkela iiodolo zesiko.

Ukuba ufuna ukwazi ulwazi oluninzi ngemveliso, nceda uzive ukhululekile uqhagamshelane nathi kwaye siya kukunika eyona mveliso ifanelekileyo kunye nenkonzo ilungileyo!

Iithegi zeMveliso

Bhala umyalezo wakho apha kwaye uwuthumele kuthi